MSO

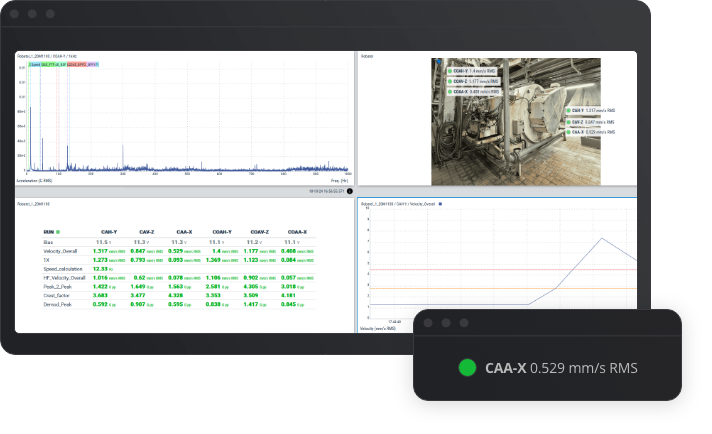

Continuous condition monitoring: Real-Time Data Processing

Condition monitoring is essential to prevent critical failures. With this predictive maintenance system, we offer a continuous and intelligent monitoring solution tailored to demanding industrial environments.

Protect and supervise your critical machines 24/7

This predictive maintenance solution integrates natively with the Machine Sentry® platform, ensuring continuous and intelligent equipment monitoring. The system supports wired sensors (vibration, ultrasound, temperature, pressure, oil and other analog signals) for advanced condition monitoring.

Thanks to its high processing power, the MSO can simultaneously sample up to 8 high-speed channels (up to 51.2 kSPS), providing precise real-time data analysis.

This condition monitoring system is compatible with most standard predictive maintenance techniques, including vibration analysis, ultrasound, temperature and electrical parameters

Unique Advantages

Continuous Real-Time Monitoring

The MSO delivers permanent monitoring of equipment, processing data in real time. This continuous surveillance detects anomalies as soon as they occur—before unplanned downtime.

Simplified Predictive Maintenance

By combining connectivity to Machine Sentry® with multi-parameter wired sensors, the solution makes it easy to deploy an effective predictive maintenance program without technical complexity. The collected data help anticipate failures and optimize interventions.

Scalable, Future-Proof Solution.

The MSO fits into a long-term industrial strategy. Its compatibility with the Machine Sentry® platform and future enhancements makes it a sustainable solution for supporting maintenance digital transformation.

Reduced maintenance costs

By anticipating failures and reducing unplanned stops, the MSO significantly lowers operating costs. Predictive maintenance extends equipment life and optimizes resources.

Why technical Experts choose the portable solution ?

Its compact format makes the system easy to transport and install on site.

Once connected, analysts can access data locally or remotely via an intuitive web interface on any device (computer, tablet, smartphone), whether in the office or working remotely.

Data sharing is simplified with web links or alert notifications by email.

La surveillance à distance devient simple, rapide et efficace.

Une solution idéale pour le condition monitoring mobile.

They use it daily :

Applications

Gas or steam turbines

Gearboxes

Electric motors

Cranes

Wind Turbines

Compressors

*Liste non exhaustive

The MSO’s compact size, low energy consumption, simplicity, performance and reliability make it a cutting-edge instrument.

Frequently Asked Questions

contact us.

What types of data graphs does the MSO provide?

The MSO offers the following display options for visualizing data:

- Spectra

- Waveforms

- Trends

- Orbits

- Phase diagrams

- Shaft centerline plots

- Cascades (Waterfalls)

If you have any further questions regarding the MSO, please contact our support team: support@digital-predict-innovation.com support@digital-predict-innovation.com

Where is the data stored on the MSO?

The MSO includes 4 GB of internal storage to save data in case of an Internet connection loss. Once the connection is restored, all data is automatically sent and stored online on the Machine Sentry cloud servers.

For more information about the MSO, please visit the product page (Link page) or contact our support team here :support@digital-predict-innovation.com

Similar products

ADA™

Your best investment

Automated Diagnostic Assistant by Digital Predict Innovation

The fixed sensor

Increased monitoring, reinforced reliability

Both fixed and agile, the MSF sensor is designed for enhanced tracking of fault evolution and for monitoring critical or hard-to-access equipment.