FIXED OIL SENSOR

Master the condition of your oils in real time, wherever your equipment operates, with the fixed oil sensor.

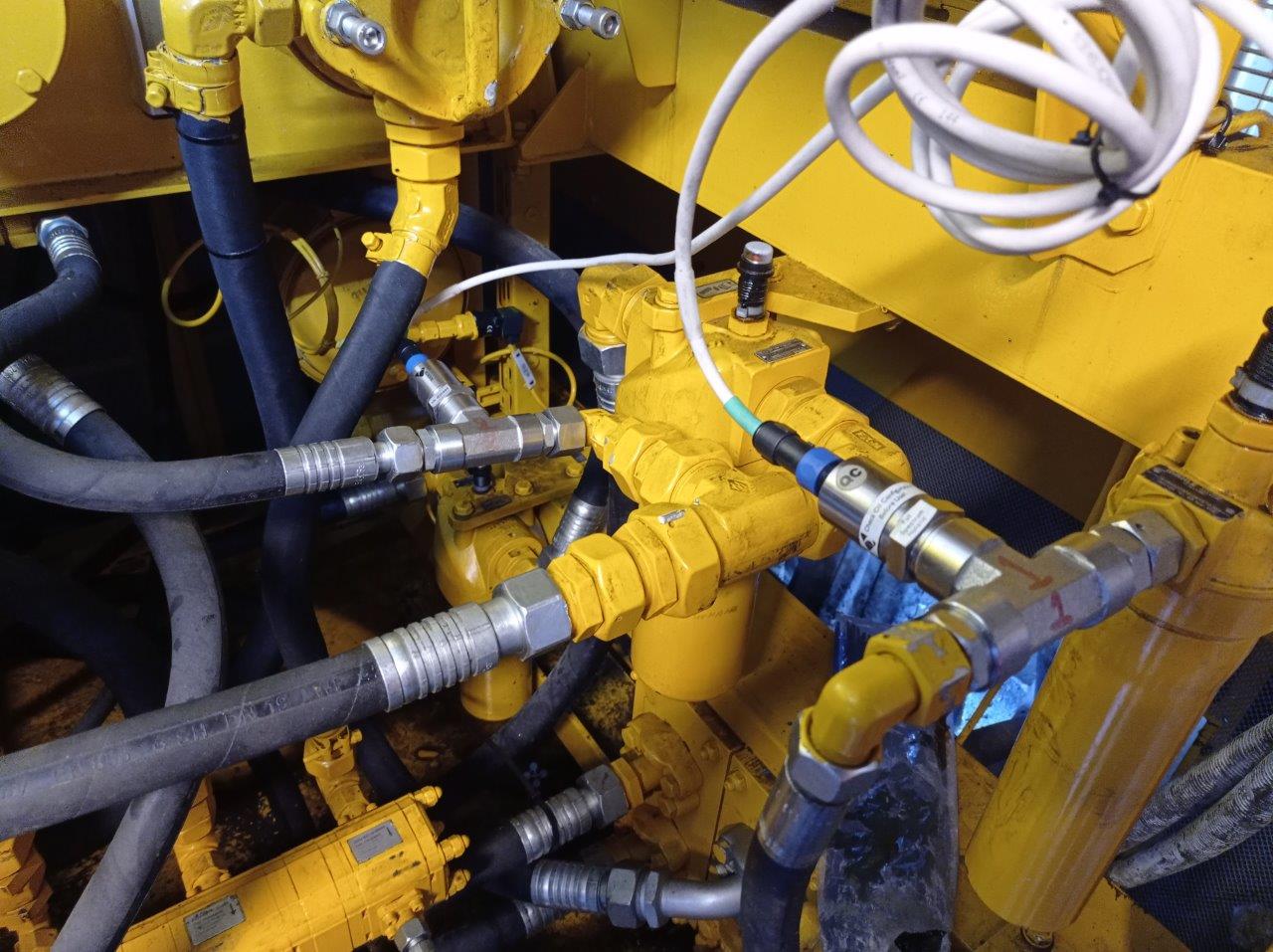

The fixed oil sensor provides real-time oil condition analysis.

enabling significant operational benefits such as reduced maintenance costs, improved equipment reliability, reduced oil waste, and extended equipment life.

Professional resource management

Improve equipment availability and boost Operational Excellence.

%

de réduction des coûts de maintenance /an

%

(100ppm) sensibilité à la contamination de l’huile

%

de réduction de la consommation d’huile /an

Unique Advantages

Real-time analysis

Continuous oil condition analysis detects and reports changes caused by wear and/or contamination in real time.

Reliable precision

Immediate detection of even the smallest oil condition changes (down to 100 ppm).

Suitable for all types of oil

The sensor can be used on any type of equipment in any environment and works with all types of oil : mineral or synthetic.

Instant results is under 1 minute !

Why use the fixed oil sensor ?

- Early problem detection

- Reduced maintenance costs

- Extended equipment lifespan

- Optimized oil change intervals

- Improved safety

- Compliance with standards and regulations

For which machines?

Mechanical gearboxes

Oil power units

Compressors

Injection presses

Diesel engines

Trasnformateurs électriques

Frequently Asked Questions

contact us.

Question ?

…

Similar products

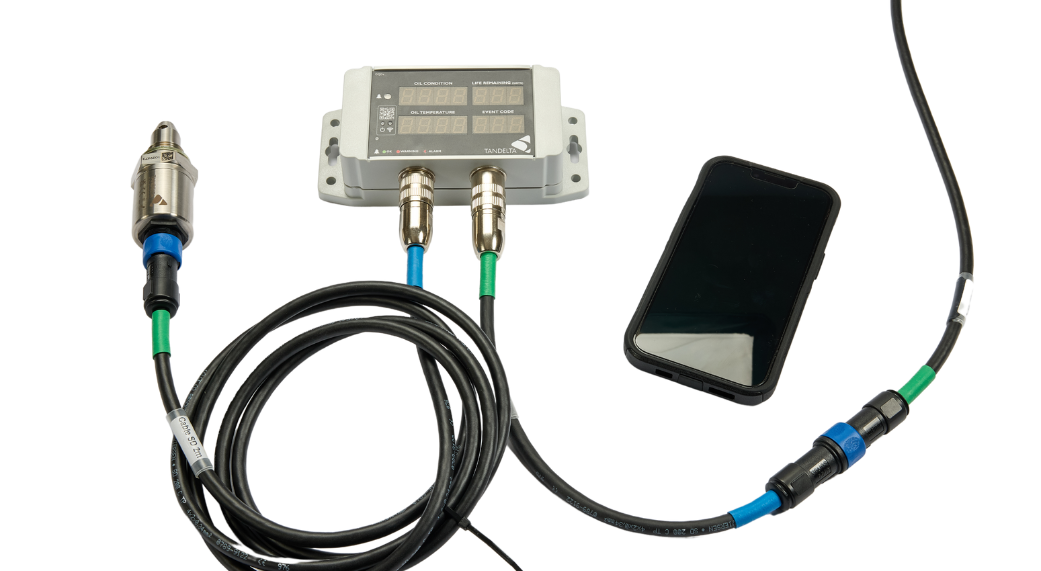

Mobile oil sensor

Monitor the condition of your oils with the mobile kit

The TDM is designed for instant on-site monitoring of your equipment's oil condition

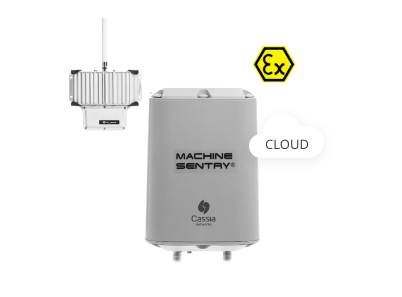

Gateway

Online gateway

Automatically connect your sensors using our connected gateway solutions.